Laser Marking

Experience the American Bright Works Advantage

Validated

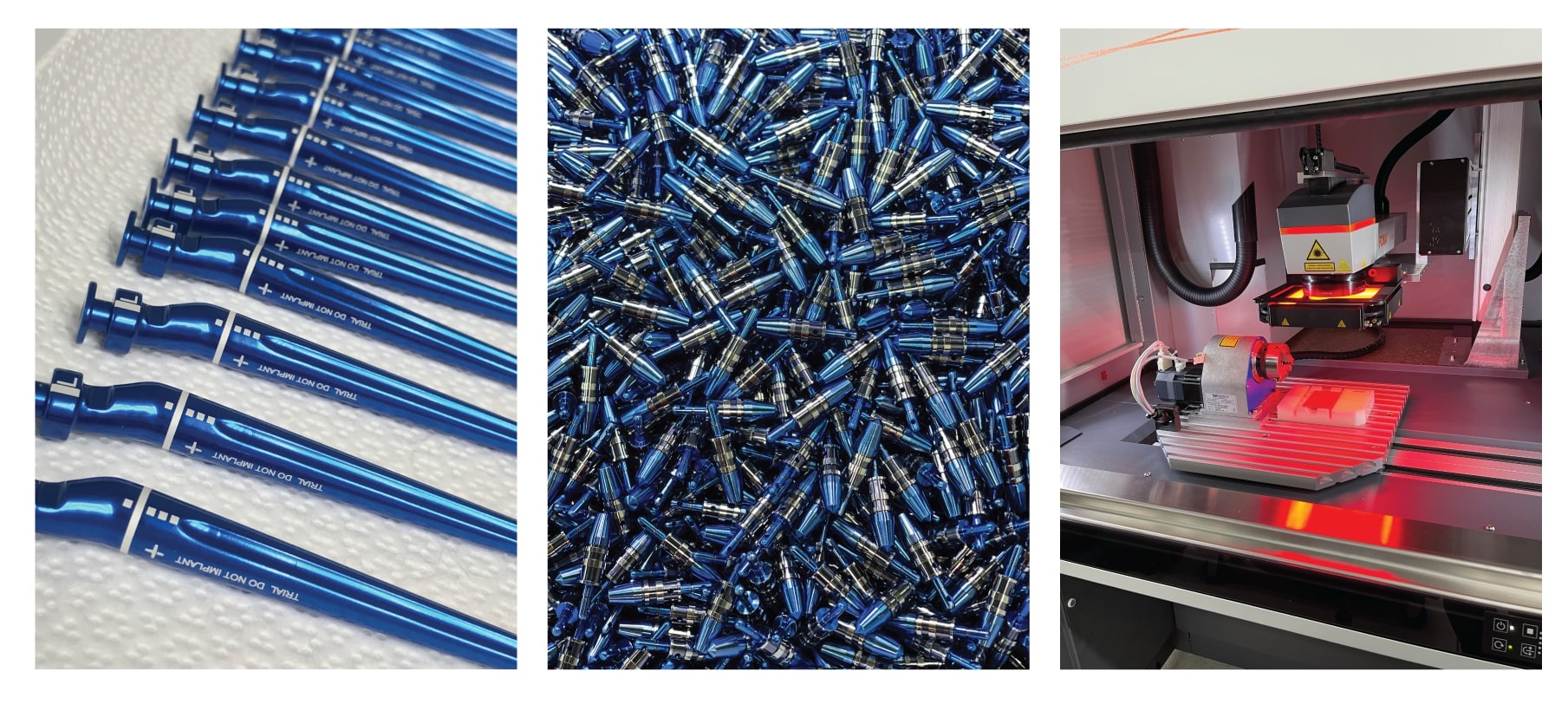

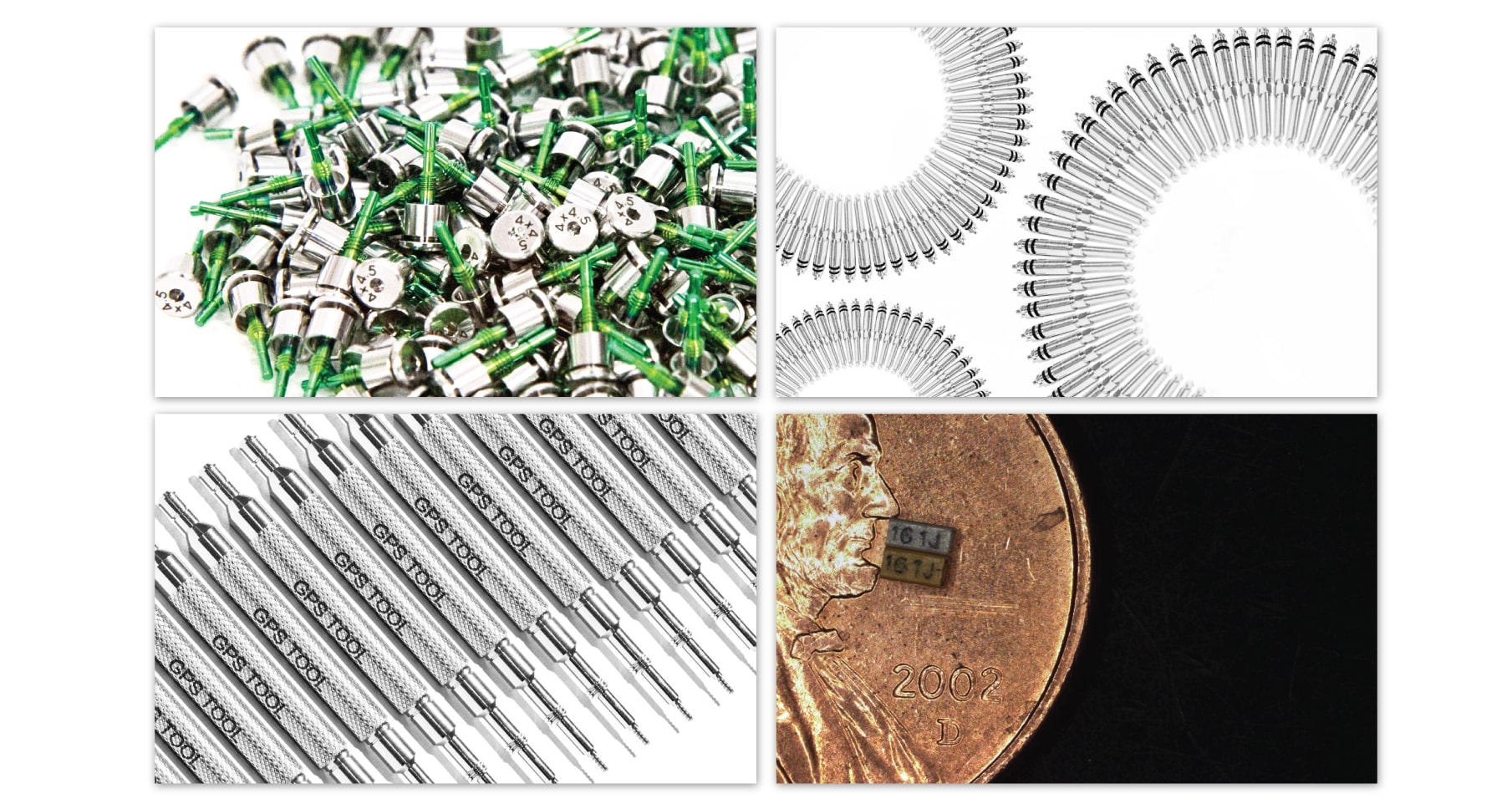

Laser marking also referred to as part marking, laser etching, or engraving has become increasingly popular in the medical manufacturing community. It is an important application for product identification and traceability on many implantable and non-implantable medical components. Many kinds of metals and metal alloys can be laser marked including various stainless steel alloys, titanium and aluminum alloys, along with a variety of plastics and other non-metallics such as ceramics, glass, wood, and leather.

Laser marking can be used for the removal or engraving of a variety of metals. During removal, a thin outer coat can be removed on anodized titanium or aluminum parts. The outer material is evaporated by the laser beam exposing the sub-layer material. For engraving, more material is removed to create a tangible impression on the surface, similar to mechanical engraving.

Solid Works Software is used for editing, engineering, and reading customer files for laser systems. Four 3D printers for making custom fixtures and masking

2 – Fusion 3 – 3D printers

2 – ultimaker – 3D Printers

Laser marking can be used to identify parts with:

- Part numbers

- Lot numbers

- Part sizes

- Sequencing

- Barcodes

- Company logos and graphics

- And more

Foba - Fiber Laser

20-Watt Fiber laser with movable table and head and rotary unit. Focus on precision vision system for marking without fixtures, capable of the following:

- Annealing

- Etching/Engraving

- Graphics, logos, barcodes, alphanumeric, etc.

- Variety of plastics, titanium, stainless steel.

- Material removal

- Foaming

- Change in color

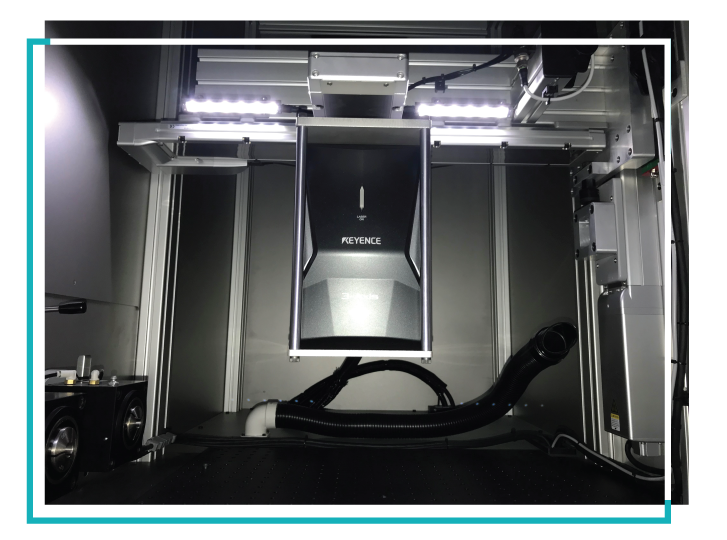

Keyence - Fiber Laser

3-Axis Fiber 50 Watt Laser with movable Head 20” in both X and Y rotaries with vision system. Capable of the following:

- Annealing

- Etching/Engraving

- Graphics, logos, barcodes, alphanumeric, etc.

- Variety of plastics, titanium, stainless steel.

- Material removal

- Foaming

- Change in color

Beamer - Fiber Laser

Beamer FB20 is a fiber laser marking system. This laser marker works by focusing a 1064 nm laser beam to the work piece via a flexible fiber cable. This allows the laser to be focused to a spot a few microns or less. With a pulse rep rate of up to 200 khz, we have found this type of laser marker to work well for marking both metallic and non-metallic parts.

30-Watt Fiber Laser with stationary head and movable Z-height capable of the following

- Annealing

- Etching/Engraving

- Graphics, logos, barcodes, alphanumeric, etc.

- Variety of plastics, titanium, stainless steel.

- Material removal

- Foaming

- Change in color

2 - Trumpf 5000-Yag Laser

Trumpf Trumark 5000, a YAG laser, for laser marking. This laser relies on an X-Y table where the workpiece or surface of the parts is typically stationary and the laser optics move in X and Y directions, directing the laser beam to draw vectors. We also have a rotary axis device which allows us to laser mark on curved surfaces for banding applications and for laser marking on diameter surfaces.

50-Watt Yag laser, stationary head, movable Z-Height with rotary. Capable of the following:

- Annealing

- Etching/Engraving

- Graphics, logos, barcodes, alphanumeric, etc.

- Variety of plastics, titanium, stainless steel.

- Material removal

- Foaming

- Change in color